Introduction

In this article, I'll be delving into the concept of predictive maintenance and its significance in contemporary applications that degrade over time.

We'll primarily examine the status monitoring of an electric drive, a component integral to modern innovations like autonomous vehicles and industrial robots.

Predictive maintenance's goal is to foresee potential system failures using the current status as a reference point.

First, we'll touch upon the basics of electrical drives and motor control, setting the stage to explore how their status can be predicted.

Electrical Drives

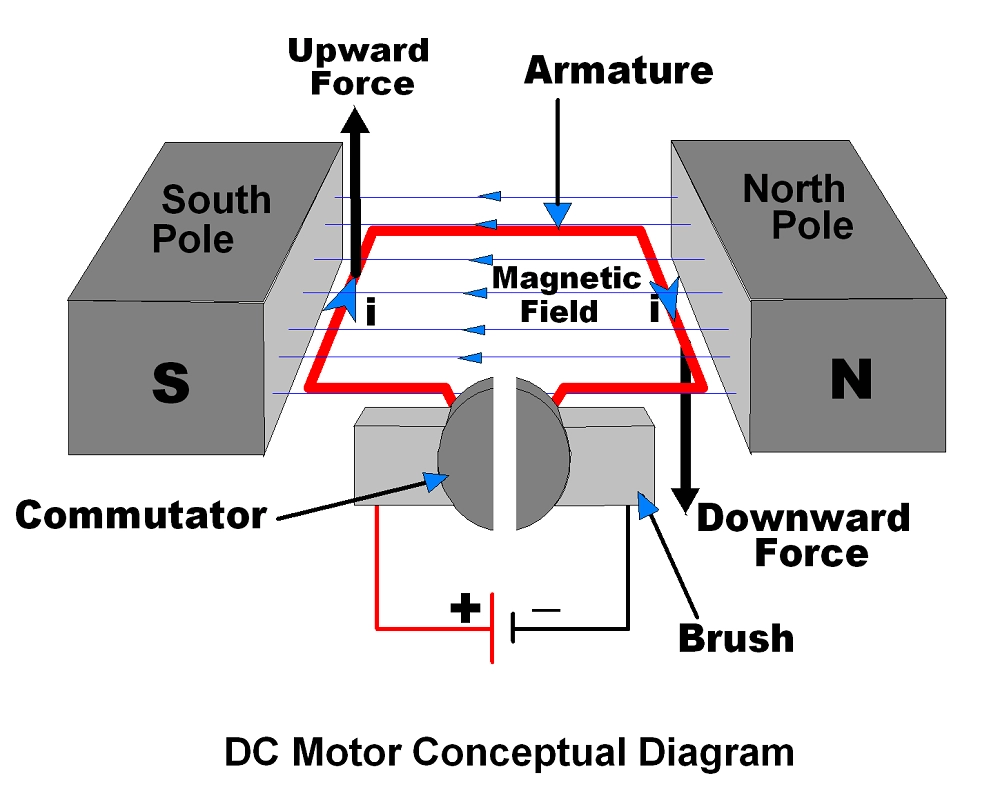

Let's start by briefly explaining the physical principles behind the operation of a DC motor:

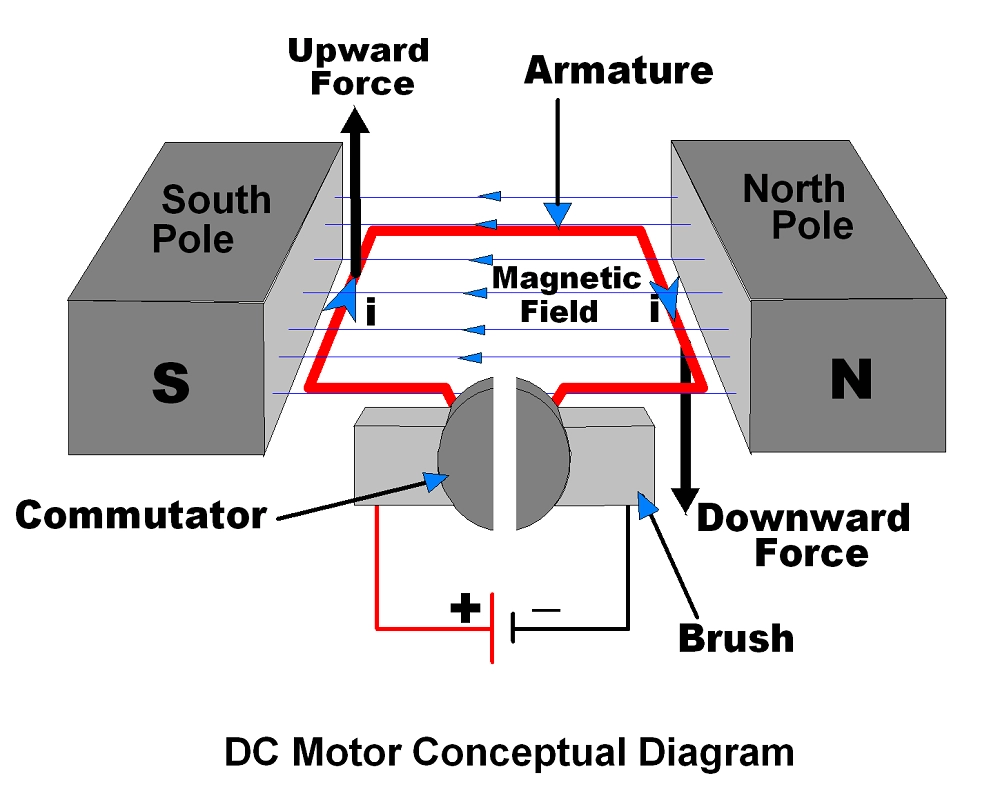

The diagram illustrates three key components:

1. Two magnets of opposite polarity: one North and one South.

2. An armature that allows for the flow of current.

3. A generator designed to create a voltage difference, enabling current to move from its positive to its negative side through the armature.

What occurs upon activating the generator?

The armature begins to rotate as soon as current flows through it. This rotation is caused by the Lorentz force. Visualizing the current as a stream of particles moving from positive to negative, when this stream is placed within a magnetic field (as is the case with the armature situated between the two magnets), the Lorentz force acts perpendicularly to the particle flow, inducing rotation.

Modern electric drives consist of an electric motor (like the DC brushed motors described) and power electronics, such as Silicon Carbide (SiC) or Gallium Nitride (GaN), which are used to control the motor.

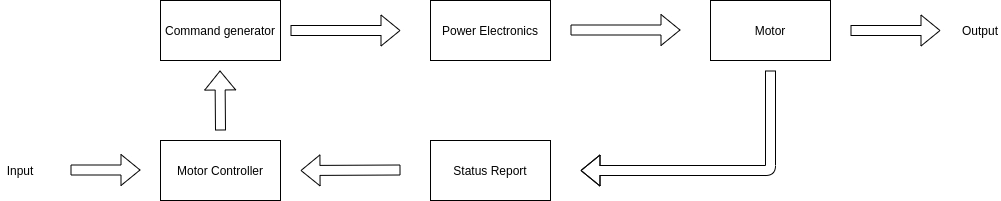

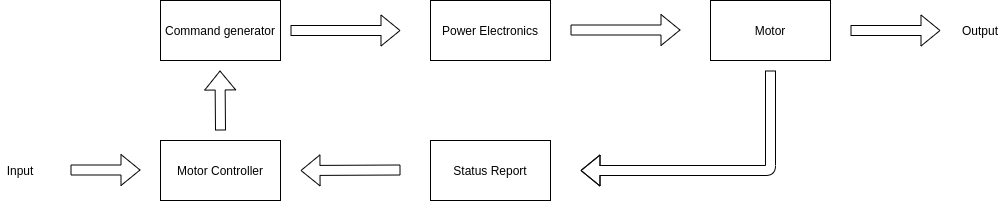

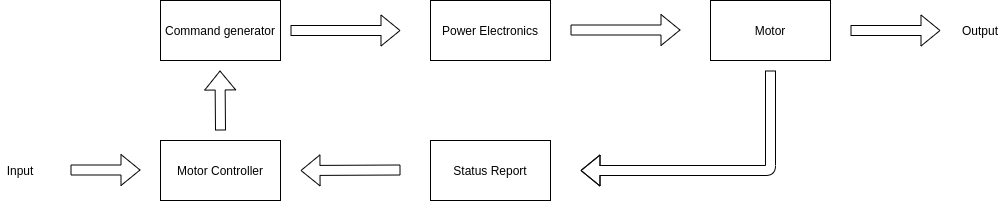

In summary, a typical reference design might include these elements:

Motor Control

The block diagram previously shown depicts an

open-loop system, where the command flows unidirectionally from the source to the motor. In such a setup, we rely on the hope that the motor will function as intended, as there is no control mechanism in place.

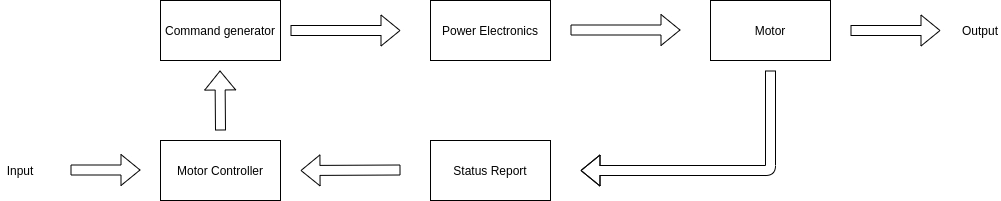

To enhance this system, we need to introduce feedback, incorporating data about the motor back into our command generator. This feedback is crucial for understanding various aspects, such as the motor's position, which in turn allows us to generate suitable inputs for the power electronics from the command generator.

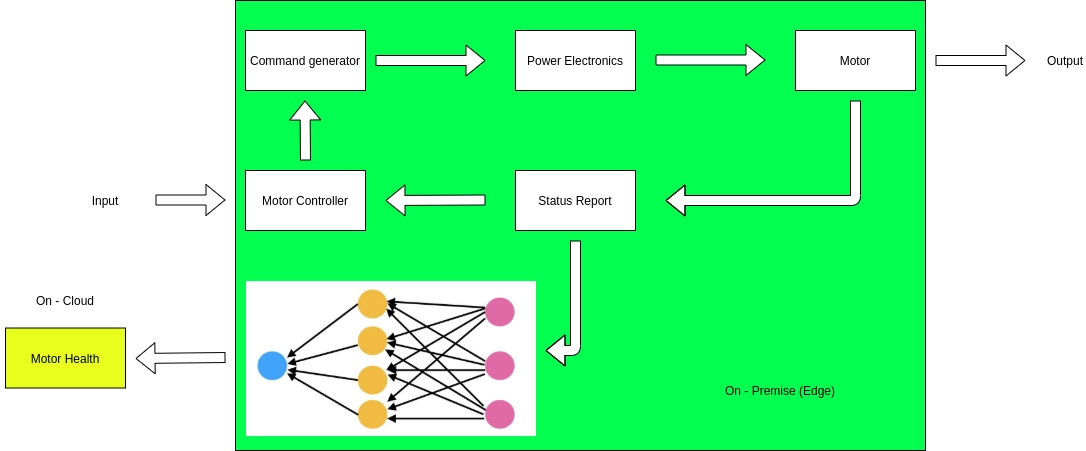

To complete and operationalize our system, we will introduce two additional components: a motor controller and a status reporter, thus transforming the diagram into a functional schematic.

Motor Health Status Reporting

With an understanding of how to control an electric drive, our next objective is to discern how to detect potential faults in the motor.

While there are numerous approaches for this, our focus will be on using Neural Networks.

Neural Networks, due to their nonlinear formulation, are adept at recognizing complex patterns in specific problems. For readers interested in a deeper dive, we have explored them in detail in another article: AI edge platform on zynq fpga.

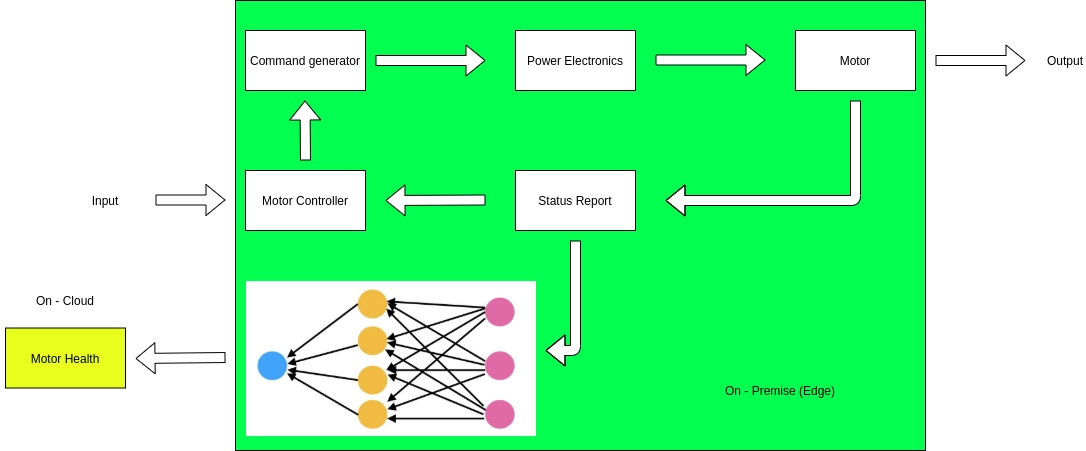

Let’s revisit the previous schematic:

How do we identify faults in this closed-loop system?

How do we identify faults in this closed-loop system?One key area to focus on is the connection from the Status Report to the Motor Controller. Here, we can employ a neural network to assess the motor’s condition, classifying it as either healthy or unhealthy.

The diagram we've discussed represents a contemporary Predictive Maintenance system. This system is adaptable to various electric drives and can provide real-time feedback (depending on the chosen architecture, for example, FPGA which computes in hard real-time) on the motor's condition.

Cloud Computing Vs Edge Computing

Now, let's briefly differentiate between edge and cloud computing. Edge computing occurs when data is processed close to its source, meaning it doesn’t rely on internet transmission. In contrast, cloud computing involves processing or storing data in a location different from where it's generated.

Predictive Maintenance is an ideal application for both edge and cloud computing. Motor control and health assessment can be conducted locally (at the edge), while health reports could be stored in the cloud, minimizing memory or database use on-site (for instance, an industry with local storage needs for customer or partner data would benefit from maximizing available memory). This setup highlights the distinction between edge and cloud computing in Predictive Maintenance.

Conclusion

This article has presented a potential application of predictive maintenance for modern electric drives using Neural Networks.

The project employs Zynq UltraScale+ MPSoCs, like the ZU3EG or ZU7EV, as its reference architecture.

I hope this article has been informative and enjoyable for the reader.

Enjoy your acceleration,

Guglielmo Zanni

Principal Scientist @MakarenaLabs – Research Fellow @Altair Laboratory

How do we identify faults in this closed-loop system?

How do we identify faults in this closed-loop system?